In the field of environmental research and material testing, accurately evaluating how materials or catalysts degrade gaseous pollutants is crucial. Whether you are studying the breakdown of formaldehyde, benzene (BTEX), or cigarette smoke components, the testing environment itself must not introduce errors. This is where a high-performance Environmental Testing Chamber becomes indispensable. The chamber must be absolutely airtight to prevent pollutant leakage, and its interior surfaces must be chemically inert to avoid adsorption, reaction, or off-gassing that could skew your results.

At vacuumdegassing.com, we specialize in providing custom enclosures that meet the most stringent requirements. Recently, we developed a solution based on a tempered glass glove box with silicone sealing, tailored to a client’s exact specifications for pollutant degradation studies. Below, we break down the key technical requirements and explain how our design fulfills them.

Based on the client’s needs, a reliable testing chamber must include the following features:

The chamber size should be adaptable to accommodate all necessary components without unnecessary bulk. Our approach: we offer customizable sizing to fit your specific setup, from small benchtop units to larger walk-in designs.

The chamber must be completely sealed to prevent any loss of test pollutants (aldehydes, ketones, BTEX, cigarette smoke, etc.). Even microscopic leaks can compromise long-term exposure studies.

Materials in contact with the test atmosphere must not react with pollutants or emit volatile compounds. Common chamber materials like certain plastics may absorb or release gases, leading to false readings.

To ensure uniform pollutant distribution, a built-in or retrofittable mixing device (e.g., a small fan) is essential. This eliminates concentration gradients within the chamber.

Internal or external electrical interfaces (such as power strips) are needed to operate sensors, fans, or other equipment inside the sealed environment.

Additional cable feedthroughs must be available for inserting external probes (e.g., gas analyzers, temperature/humidity sensors) without breaking the seal.

A door, lid, or glove port access is required to place samples, arrange components, and perform manual adjustments inside the chamber.

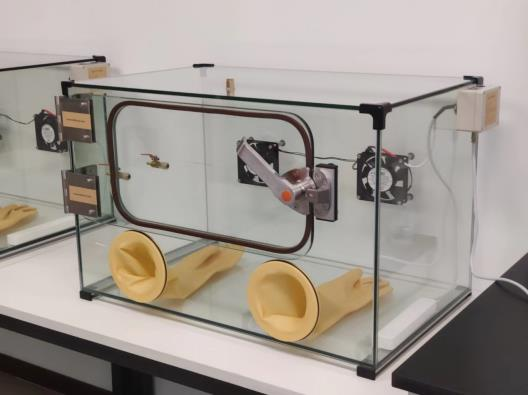

To meet all these demands, we provided a custom Environmental Testing Chamber built around a tempered glass glove box. Here’s how it addresses each requirement:

The chamber is constructed from tempered glass panels, which are inherently chemically inert—they do not react with most pollutants and do not outgas. All joints are sealed with high-quality silicone, a material known for its low volatility and excellent sealing properties. This combination ensures zero leakage and no background interference, even during extended tests with trace-level pollutants.

We integrated an internal low-speed fan to gently circulate the air, preventing stratification and ensuring that the test atmosphere remains uniform. The fan can be controlled externally or via a timer.

Multiple hermetic feedthroughs are installed to accommodate:

These ports are designed to maintain the chamber’s seal while allowing flexible connectivity.

In addition to standard ports, we included extra cable channels sealed with removable plugs. This allows researchers to introduce new probes or sampling lines as their experimental setup evolves.

The chamber features glove ports with durable gloves, enabling users to manipulate samples, rearrange test pieces, or install equipment without opening the main door. A large hinged door also provides full access when needed. Internal adjustable shelves (made of inert materials) help organize components efficiently.

This custom-designed Environmental Testing Chamber is ideal for:

Its robust construction ensures reproducible results, free from artifacts caused by chamber interactions.

Off-the-shelf chambers often compromise on one or more critical parameters—perhaps they lack true inertness, or they don’t allow easy probe insertion. By working with us, you get a tailor-made enclosure that aligns perfectly with your experimental protocols. We can adjust dimensions, add specialized feedthroughs, or integrate monitoring systems upon request.

When every part per billion counts, your testing environment must be a neutral, sealed vessel. Our tempered glass glove box Environmental Testing Chamber delivers the airtightness, chemical inertness, and operational flexibility required for cutting-edge pollutant degradation studies.

Interested in a custom chamber for your lab? Contact us today to discuss your specifications, or explore our other vacuum and degassing solutions at vacuumdegassing.com.

| Contact with Steven Lee | steven@vacuumdegassing.com |

| Our working time | All day and night, as you need. |