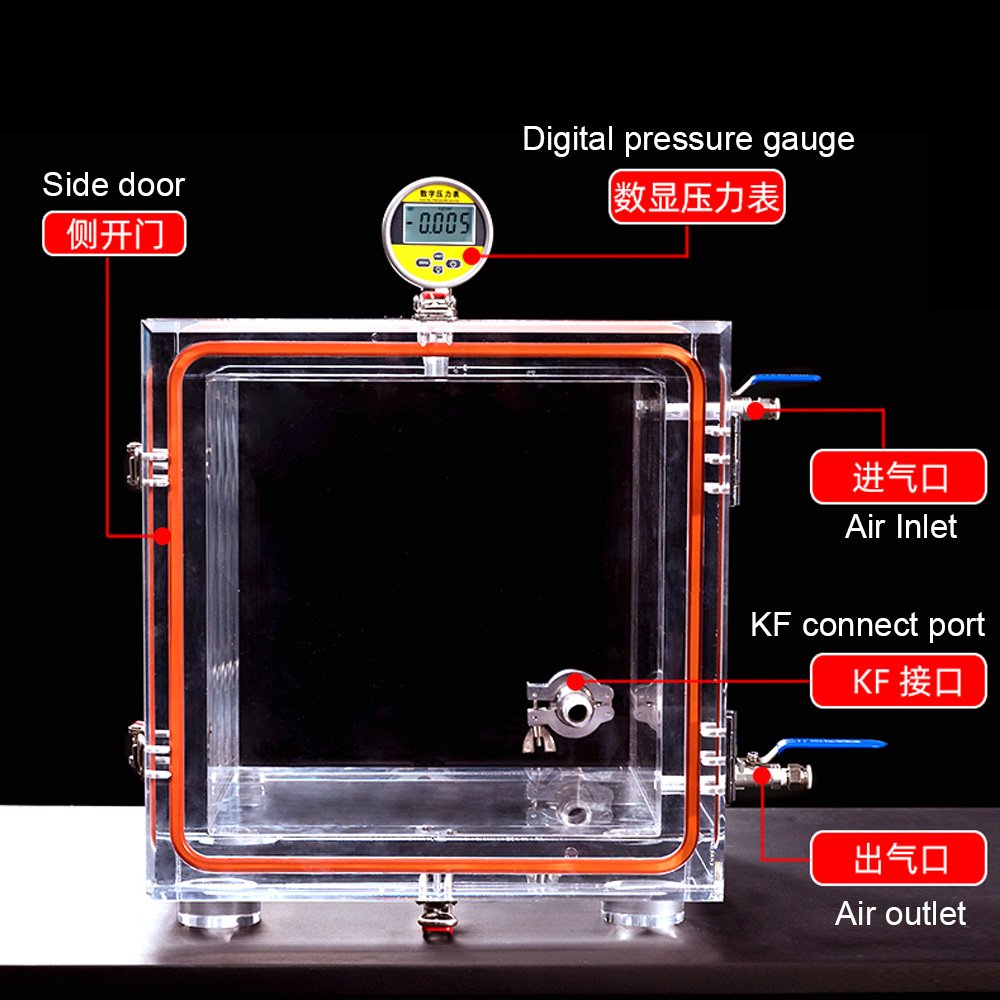

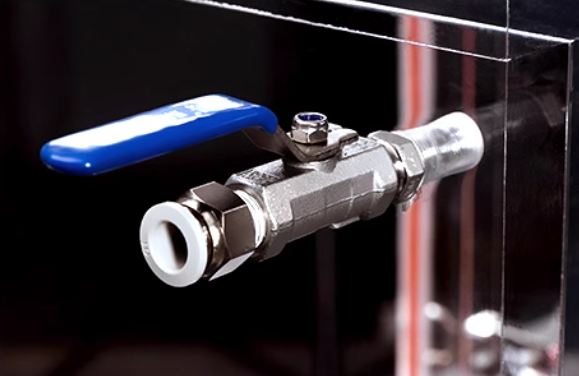

The Acrylic Vacuum Chamber is an indispensable device for a variety of sectors, including packaging, electronics, automotive, and scientific research. Constructed from high-quality transparent acrylic, this chamber is engineered to efficiently eliminate air bubbles and impurities from substances such as adhesives, resins, and potting compounds. Its clear design enables users to monitor the vacuum process in real time, ensuring optimal performance.

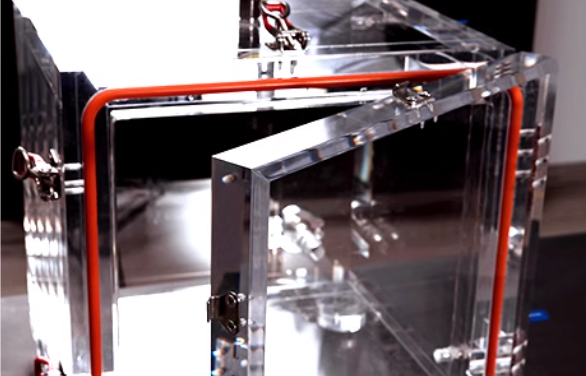

This versatile chamber is perfect for conducting sealing tests, which are critical for quality assurance in the production of sealed components. By creating a controlled vacuum environment, the acrylic vacuum chamber significantly enhances product integrity and durability. Key applications include potting electronic devices, producing vacuum-sealed packaging, and crafting high-quality molds.

Beyond its functionality, the acrylic vacuum chamber is designed for user-friendliness, featuring easy operation and maintenance. Its compact size makes it suitable for a range of workspaces, while using non-toxic materials promotes a safer working environment.

Whether you aim to streamline your production process or achieve superior product quality, the acrylic vacuum chamber is the ideal solution. Discover the benefits of this innovative equipment and see how it can boost efficiency and reliability in your operations.

Optional:

| Model | Material | Chamber Size | Side Door Size | Thickness | Vacuum degree |

| ACR250 | Acrylic | 250*250*250mm | 250*250mm | 25mm | -0.1MPA |

| ACR300 | Acrylic | 300*300*300mm | 300*300mm | 30mm | -0.1MPA |

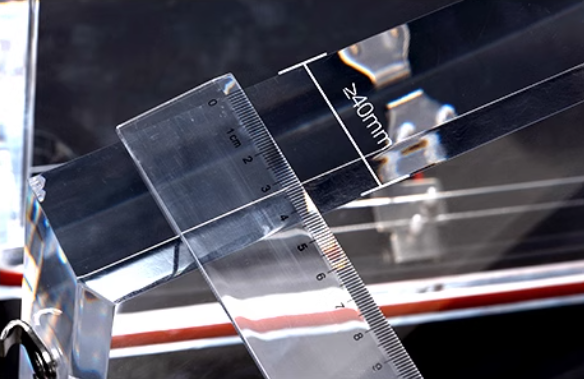

| ACR400 | Acrylic | 400*400*400mm | 400*400mm | 40mm | -0.1MPA |

| ACR500 | Acrylic | 500*500*500mm | 500*500mm | 50mm | -0.1MPA |

| ACR600 | Acrylic | 600*600*600mm | 600*600mm | 50mm | -0.1MPA |

Other customized size, please feel free to contact with us.